Description

RELIABLE AND PRECISE

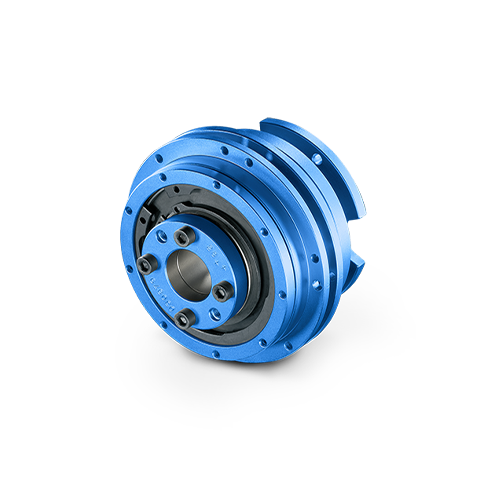

Reliable and precise: disengaging safety couplings from the ARPEX portfolio

- Releasing overload coupling (disk spring system)

- Fourteen sizes from 13 Nm to 65,000 Nm cut-off torque in two design variants

- High repeat accuracy

- Temperature range: – 30 °C to + 80 °C

- Backlash-free torque transmission

ARPEX safety couplings are used wherever reliable protection against overload is required for modern, high-quality and therefore increasingly expensive machines.

The use of ARPEX safety couplings prevents long downtimes and repairs due to overload damage in machine systems, thereby maintaining the economic efficiency of the system.

The safety coupling interrupts the flow of force in the machine system within a very short time, protecting both man and machine from damage.

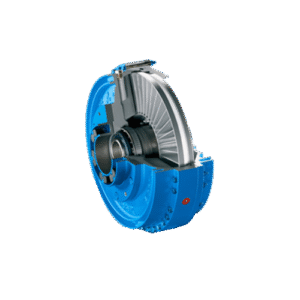

How it works:

ARPEX torque limiters work with close fitting and positively engaged splines. During normal operation of the machines the splines are kept in engagement by the spring tension of the plate springs, and so the torque is transmitted from the hub over the disc pack to the indexing rings.

In the case of overload the indexing rings turn relative to each other and press the splines out of engagement. At a defined point of the contact ratio the plate springs jump into a negative position. The splines are no longer in gear, the indexing rings have no contact and the torque transmission is interrupted.

There are two types of coupling to choose from:

- Standard version ARPEX AKR

Suitable for combination with standard components from the ARPEX and N-EUPEX range - Push-on version ARPEX AKA

Suitable for combination with various drive elements such as pulleys and sprockets

ARPEX safety couplings are available in fourteen sizes for torques from 13 Nm to 65,000 Nm (higher cut-off torques on request).

Your benefits at a glance

- Clear cut-off

The ARPEX safety coupling disconnects the coupled units when the cut-off torque is reached, both with slowly and rapidly increasing torque. - Complete disconnection

After the switching process, the two coupling halves are contact-free so that the driven machine can coast down without wear, unlike other overload coupling systems. - Degressive characteristic curve

The system torque decreases immediately when the coupling disengages due to the degressive characteristic curve of the disk springs. - Switching process

No forces are transferred to the connected machines during the switching process. The forces remain in the safety coupling system. - High repeat accuracy

The preset disengagement torque of the safety coupling is achieved with high accuracy even after frequent switching operations. The repeat accuracy is +/- 10 percent. - Fixed point switching

The coupling is always engaged in the same position due to the geometry of the face gearing and fixed point markings. - Backlash-free torque transmission

The torque is transmitted positively and backlash-free by means of full-surface face gearing.

Produced in Germany, in use worldwide

- Rubber and plastics: single and twin-screw extruders

- Oil and gas: pumps, fans, compressors, air condensers

- Energy generation: air condensers, generators, cooling towers

- Chemicals and pharmaceuticals: dryers, lauter tuns, pumps and compressors, mixers, cooling towers, agitators, reactors

- Pulp and paper: wood grinders, waste paper, wet end, dry end, calenders and cylinders, waste water treatment plants

- Water and waste water: aerators, water screw pumps

- Food and beverages: lauter tuns, reactors, agitators, mixers

Reviews

There are no reviews yet.